About Us

Sealand’s origins began in the 1950s when the company founder Jim Whitaker began installing machinery on ships, this developed into a full manufacturing business supplying bilge, ballast and oil fuel systems and cast steel ship’ side valves for the marine industry.

Over the years Sealand’s ability to solve design solutions resulted in their valves being used across the world; in manufacturing plants, the petrochemicals, oil and gas industry, on floating platforms, as well as MOD installations. Sealand still has a global customer base supplying the marine and land-based utility companies with bespoke made to measure valves.

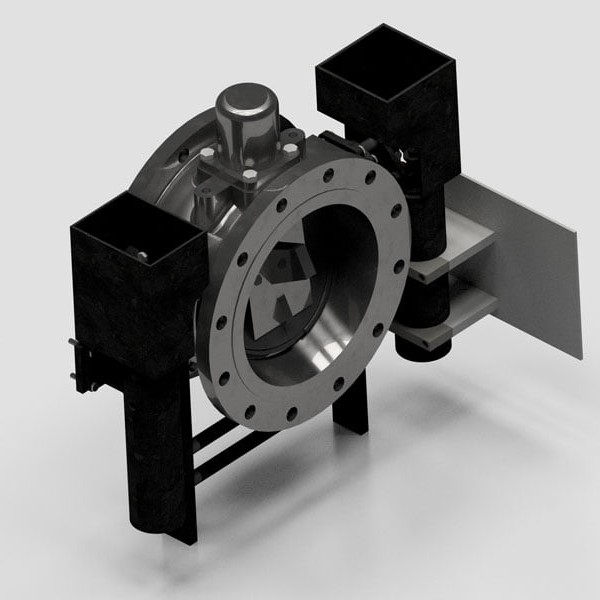

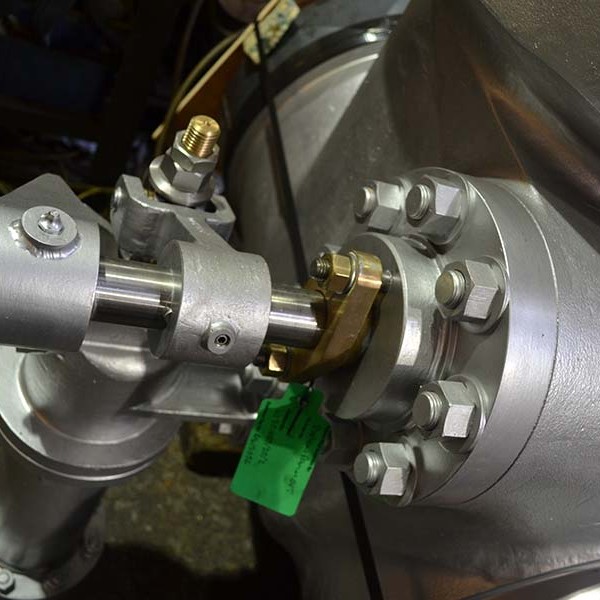

Sealand Valves have the capacity and capabilities to design and manufacture a wide range of valves. Their speciality is offering a bespoke valve design and manufacturing service, finding solutions when standard and mass-produced valves are not suitable. We have the capacity to manufacture non-standard and large bore wedge gate valves, globes and swing check in cast iron, carbon steel and bronzes as well as the exotic alloys. A typical Sealand valve will generally have one or more ‘special’ features; It might be a non-standard bore face, flange drilling, face to face or an unusual trim or a combination of these. Our capabilities range from one-off requirements to small batches and we have delivered individual products up to three tonnes in finished weight. Our products are designed and manufactured to order, meeting the material, dimensions and installation and certification requirements of our clients.

In June 2017, Acetarc Engineering, a manufacturing company with a global customer base, who supply into the foundry industry, acquired Sealand Engineering, both companies have a similar heritage, family-run businesses, with their roots in a time when UK engineering and manufacturing was at the forefront of design and innovation. Acetarc had provided sub-contract machining services, for Sealand, for many years, and their workforce were very familiar with the machining requirements of valve manufacturing.

The acquisition of skills, machinery and knowledge will enable Sealand Valves to continue to grow and flourish. They are now located in a new purpose-built factory alongside Acetarc. Sealand will still retain their ability to design and handcraft valves, whether it is to design a one-off valve or solve an installation problem in existing pipework, but they will be complemented by the other companies within Acetarc’s group of companies.

There has been considerable investment in new machinery and training, including a 3D CAD system and staff training, via the BVAA, to meet the legal requirements of the P.E.D and international manufacturing standards. This will enable Sealand Valves to offer a product that is both competitively priced but will also guarantee the buyer reassurances that their valve has been manufactured using the highest quality of materials and workmanship.